Smart Port Challenge 2023

Innovation Opportunities

This year’s Smart Port Challenge offers 13 innovation opportunities that address 5 key categories:

- Smart Port

- Smart Ship

- Smart Maritime Services and Supply Chain

- Green Technology & Decarbonisation

- Crew Safety, Training and Wellbeing

Scroll down to explore each innovation opportunity. A series of roadshows were organised in June and July to shed more light into each Innovation Opportunity.

Recordings of these sessions have been made available on PIER71 YouTube channel. Do click on the subscribe button to be notified of the latest videos uploaded.

Also follow us on LinkedIn, Instagram and Twitter for the latest updates on Smart Port Challenge 2023.

The Supporting Corporate Sponsors of these innovation opportunities are:

Building Confidence in Ammonia: How Can We Build Confidence in Ammonia as a Marine Fuel?

Green Technology & Decarbonisation

Ammonia is a viable zero-emission marine fuel. It can help meet greenhouse gas reduction targets set by governments, and a recent survey of shipping sector stakeholders by Lloyd’s List – the maritime publication – and LR identified ammonia as o...

Accelerating Biofuel Adoption: How Can We Increase the Adoption of Biofuels Through Assurance of their Quality and Traceability?

Green Technology & Decarbonisation

Biofuels are a promising option for the maritime sector to reduce its greenhouse gas emissions, owing to their “drop-in” characteristic: the ability to replace conventional maritime fuels without substantial modifications. However, the adoption ...

Preparing for Electrification: How Can Electrification Technology and Infrastructure meet the Efficiency and Cost Requirements of the Maritime Sector?

Green Technology & Decarbonisation

From 2030, all new harbour crafts operating in Singapore’s port waters must be fully electric, be capable of using B100 biofuel, or be compatible with net-zero fuels such as hydrogen. However, the lack of onshore and offshore charging stations, ...

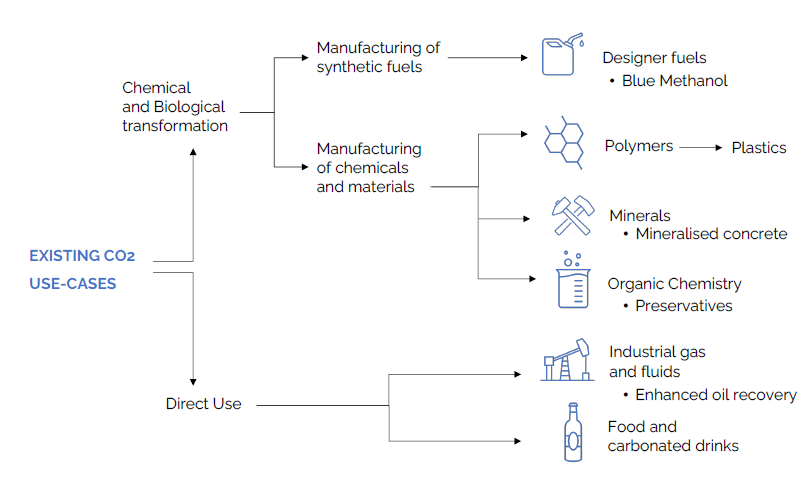

Transforming Carbon: How Can We Best Utilise Carbon as a High-Value Waste Stream?

Green Technology & Decarbonisation

For too long, carbon dioxide has been perceived as a waste product, with detrimental effects on the planet. However, with the increasing urgency to reduce carbon emissions, it is imperative to shift our perception and explore how carbon dioxide can b...

Greening the Supply Chain: How Can We Enhance Transparency, Traceability, Regulatory Compliance, and Accountability at a Sector-Wide Level to Enable a Green Maritime Supply Chain?

Green Technology & Decarbonisation

Singapore has committed to achieving net-zero emissions by 2050. In March 2022, MPA and industry partners released the Maritime Singapore Decarbonisation Blueprint 2050. However, Singapore’s maritime sector transcends borders, various stakeholders...

Improving Real-time Port Productivity: How Can We Streamline Communication and Have Real-Time Operational Overview of Vessel Activities in Port?

Smart Port

Jurong Port is a multipurpose port operator that provides berthing facilities for vessels and facilitates loading and unloading cargo from ships. However, ground staff overseeing terminal operations do not have efficient way to communicate effectivel...

Voyage Optimisation: How can we enable better interconnectivity and interoperability between ships and port systems?

Smart Port

Smart Ship

Schulte Group and Innoport are the proposers of this innovation opportunity. This is an industry challenge, not specific to only a single corporate, but Schulte Group will be one of the sponsors and trial partners; such as engaging the resources f...

Improving Cement Removal Process: How Can We Remove Cement Residue in an Automated, Effective, and Efficient Manner?

Smart Port

Cement carrier vessels play a significant role in transporting cement, a key building material for the construction of infrastructure. However, during the unloading of cement from the vessel, there is often leftover residue that might be difficult...

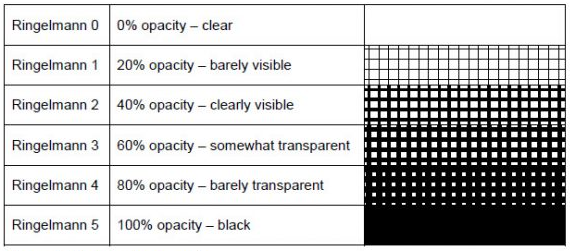

Black Smoke Emission: How Can We Capture Dark Smoke Emission?

Smart Port

Ships emit black smoke due to incomplete combustion of fuel, which results in the release of small carbon particles harmful to human health and the environment. The quality of fuel used by ships, engine performance, and operational conditions affect ...

Improving Real-time Warehouse Hub & Hub-Port Productivity: How Can We Gain Full Visibility of Warehouse Hub Operations, Facilities and Assets Utilization?

Smart Maritime Services and Supply Chain

As a supply chain orchestrator, apart from overseeing cargo and container flow, PSA also serves as a hub operator, managing a multi-tenanted warehouse. Currently, there is no integrated system that allows real-time visibility on how assets are uti...

Driving Cyber Readiness: How Can We Improve the Maritime Sector’s Cyber Readiness?

Smart Maritime Services and Supply Chain

As Singapore’s maritime sector digitises, and with the 2030 electrification target, the likelihood of cyber-attacks increases. Attacks are becoming more sophisticated and undetectable, targeting both insecure systems and human behaviour. With incr...

How Can We Make Marine Insurance More Efficient for the Customer and Insurer – Through Risk Prevention or Mitigation? How Should Insurance Respond to Emerging Marine Trends?

Smart Maritime Services and Supply Chain

Artificial intelligence, machine learning, digital twins, renewables, autonomous vehicles, drones, robotics leverage modern technologies to improve efficiencies, safety, sustainability and performance in smart ports, ships, logistics and maritime ser...

Wireless Connectivity in Port Waters: How Can We Enable Electronic Transactions and Data-Intensive Applications in Port Waters?

Smart Port

Smart Ship

The Maritime and Port Authority of Singapore (MPA) is driving the digital transformation of the maritime industry and positioning our Hub Port and International Maritime Centre for the future.

Open Category

Smart Port

Smart Ship

Crew Safety, Training and Wellbeing

Smart Maritime Services and Supply Chain

Green Technology & Decarbonisation

In addition to these 13 innovation opportunities, start-ups with technologies or solutions that can address Smart Port, Smart Ship, Smart Maritime Services and Supply Chain, Crew Safety, Training & Wellbeing, Green Techn...